Used in the industrial construction, by laboratory tests and fulfilling scientific work, vision systems realize automatic conducting of operations for quality control of products, caused by getting more and more stringent requirements to compliance of the produced goods to quality standards and the inconvenience of control carried out “by hand”. Introduced computer technologies at the expense of automation provide the growth of labour productivity and, respectively, growth of the speed and quality of the production. Using special software which is part of machine vision system guarantees absence of human factor mistakes in the work results.

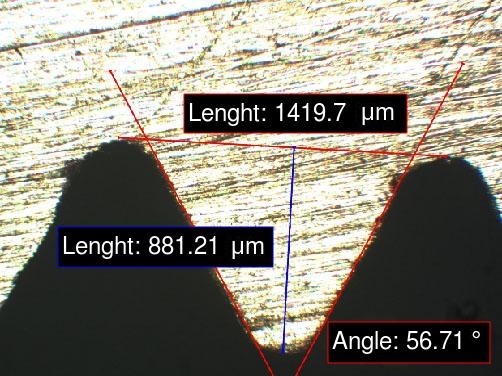

Conducting visual analysis and processing of video data, as well as measurements by defining quality, in most cases are applied for finding different defects of the examined products (by defectoscopy, surface control, etc). Production can be made of different materials, metal, glass, any textile, etc.

Altami systems of machine visions make the following operations, providing automation of production quality control in industry: capture of the object image; its automatic analysis and processing, as well as conducting measurements; return of the received data in the form in which it is convenient for the user. For example, according to the results of measurements, both automatic and conducted by hand with the help of the software, the application shows statistics which helps in classifying the examined objects. By finishing the work in the application, it is possible to create the report on the work and the received results.

For example, following the results of the computer analysis and processing images for finding outer defects a conclusion on eligibility of products is made, and if the defects are found — their size is assessed and classification is made on the basis of statistics received in the application.

One of the advantages of Altami vision systems is the fact that they provide automatic processing of images in real-time mode, that is, operations necessary for quality control can be conducted on static images and on video stream “live”.

Altami technical vision systems are often applied together with microscopes of the same brand. For example, Altami Studio application, at first worked out as an application for microscopes, and delivered with the laboratory equipment, is used for control of accuracy of detail making, and for finding the unacceptable ones. Areas of applying: electronics, machine-building, metallurgy, medicine, and so on.

Software Altami used for:

You can read the article on the example of the use of Altami Studio application for conducting quality control which is called Quality control for ring seal fittings and pipe thread identification.

In the electronics industry in the manufacture and quality control of printed circuit boards can be used Altami software solution for automatic recognition of the resistors and determination their nominal resistance.

Altami software products work under the most popular modern operating system such as Windows, Linux и Macintosh.

If our products do not solve your problems, we are ready to develop "from scratch" or modify existing applications.

Tired of the slow camera work? Keep up with progress! The camera on USB 3.0! operates at a speed of up to 180 fps.